2023.12.18

Imported recycled plastics quality safety risk and typical case analysis

Page view:409

Major risks in the regulation of imported recycled plastics

Major risk

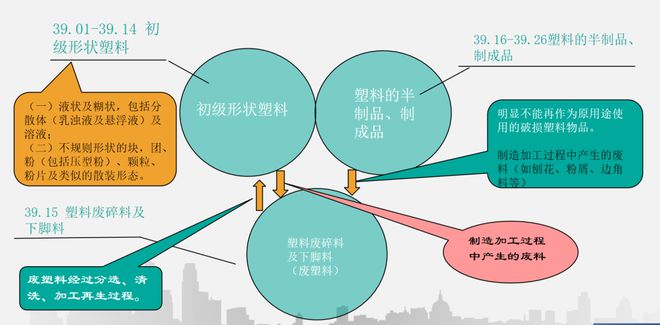

(1) Recycled plastics belong to the emerging field, there is no corresponding tax number at present, and it is necessary to refer to the primary shape of raw materials for classification.

(2) The quality of recycled plastics is uneven, and the properties of solid waste are not clear

Types of plastic solid waste mainly involved

"GB 34330-2017 Solid waste identification Standard General Rules", gives the definition of solid waste and general judgment principles, for specific plastic solid waste, mainly involves:

(1) Waste and scraps of thermosetting plastics.

(2) Waste plastic items that can no longer be used for their original purposes, as well as scraps, scraps, defective products, waste materials (shavings, powder, etc.) generated in the process of plastic manufacturing and processing.

(3) Low-end recycled plastics, including an uneven mixture of waste scraps, scraps and scraps of two or more kinds of plastics, are still solid waste, even if they have been processed into primary shapes.

A key factor in importing recycled plastics

Factor 1: Appearance, material consistency, uniformity. (Composition analysis, melt flow rate deviation, density deviation, etc.)

Determine whether the waste plastic has been sorted, cleaned, processed and recycled.

Factor 2: Odor, toxic and harmful substances (radioactivity, heavy metals, phthalates, polybromine, residual monomers, etc.)

Determine whether it comes from waste plastics that have been contaminated, whether there are illegal additives in the reprocessing process, or whether serious degradation has occurred.

Factor 3: Performance indicators (tensile properties, bending properties, impact properties, etc.)

Judge the value of subsequent processing and utilization, market value, etc.

Typical case analysis

Case 1

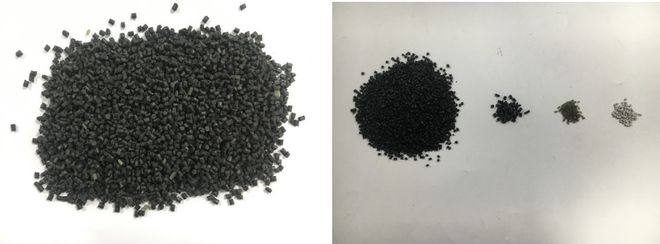

1, the main material analysis: the sample is mainly black particles, particle size is not uniform, the main component of the sample is polyvinyl chloride.

2. The samples were tested, and the results showed that the proportion of large and small particles was 76.6% (mass fraction), and the proportion of normal particles was 23.4% (mass fraction).

3. Odor analysis: The sample has odor, but no disturbing pungent odor, and the rating result is 2.0.

4, heavy metals, polybrominated biphenyls and polybrominated diphenyl ethers, phthalates and other restricted substances analysis results show that the heavy metal lead content is 5321mg/kg (standard limit requirement is 1000mg/kg).

5. Conclusion: The sample is polyvinyl chloride recycled plastic particles processed from waste plastics, mixed with waste plastics produced in the process of waste plastic reprocessing, and the lead content of harmful substances does not meet the requirements of GB/T 40006.1-2021 standard on restricted substances, the sample is polyvinyl chloride recycled plastics and its waste contaminated by harmful substances lead. According to GB 34330-2017, the sample was determined to be solid waste.

Case 2

1, the main material analysis: the sample is black particles, particle size is not uniform. The main component of the sample was polystyrene.

2. Odor analysis: The sample has odor, but no disturbing pungent odor, and the rating result is 3.0.

3. Analysis results of heavy metals, polybrominated biphenyls, polybrominated diphenyl ethers, phthalates and other restricted substances showed that the content of polybrominated diphenyl ethers was 7890mg/kg (the standard limit requirement was 1000mg/kg).

4. Conclusion: The sample is polystyrene styrene recycled plastic particles processed from waste plastics, and the content of harmful substances polybrominated diphenyl ether does not meet the requirements of restricted substances in GB/T 40006.1-2021 standard. The sample is polystyrene recycled plastic contaminated by harmful substances polybrominated diphenyl ether. According to GB 34330-2017, the sample was determined to be solid waste.

Case 3

1, the main material analysis: the sample is composed of light brown particles and dark brown particles, light brown particles thickness is not uniform, the main components are low-density polyethylene (density ≤0.940g/cm3).

2. Odor analysis: The sample contains a strong pungent odor, and the rating result is 5.0.

3, heavy metals, polybrominated biphenyls and polybrominated diphenyl ethers, phthalates and other restricted substances analysis results meet the requirements.

4. Test the tensile properties of the sample according to GB/T 40006.2-2021 standard.

item

Tensile strength, MPa

Tensile fracture nominal strain, %

Sample test result

11.4 (≥12)

101 (≥200)

5. Conclusion: The sample is uneven recycled plastic, the odor does not meet the requirements of GB/T 40006.1-2021, and the tensile strength and nominal strain properties of tensile fracture do not meet the requirements of GB/T 40006.2-2021. According to GB 34330-2017, the sample was determined to be solid waste.

Case 4

1, the main material analysis: the sample is black plastic particles, the particle size is basically the same, the naked eye can see that the particles are coated with impurities inconsistent with the color of the body. The main component of the sample is polyethylene-polypropylene blend (mainly polyethylene), and the main component of the impurity is polyester.

2. Odor analysis: The sample has odor, but no disturbing pungent odor, and the rating result is 2.0.

3, heavy metals, polybrominated biphenyls and polybrominated diphenyl ethers, phthalates and other restricted substances analysis results meet the requirements.

4, Conclusion: The recycled plastic obtained from the sorting of unclean waste plastic granulation, the sample material is not uniform, which belongs to the waste plastic reprocessing process. According to GB 34330-2017, the sample was determined to be solid waste.

Case 5

1, the main material analysis: the main component of gray particles and brown particles is polyamide 66 (PA66), the main component of dark brown particles is polyamide 6 (PA6).

2, odor analysis: the sample has obvious odor, but no interference stinging, exciting odor, rating result is 3.0.

3, heavy metals, polybrominated biphenyls and polybrominated diphenyl ethers, phthalates and other restricted substances analysis results meet the requirements.

4. Conclusion: The samples are plastic particles with different colors and different compositions mixed after processing of waste plastics, indicating that the samples come from the mixed materials, scraps and transition materials produced in the production process of different production processes. According to GB 34330-2017, the sample was determined to be solid waste.

Case 6

1. Main material analysis: The main component of black particles is ABS, and some black particles are ABS/PC blends; The main component of white particles is ABS/PC blend; The main component of green particles is PC.

2, odor analysis: the sample has odor, but no interference stinging, exciting odor, rating result is 5.0.

3, heavy metals, polybrominated biphenyls and polybrominated diphenyl ethers, phthalates and other restricted substances analysis results meet the requirements.

4. Conclusion: The samples are plastic particles of different colors and different compositions mixed after processing of waste plastics. The samples come from the mixed materials, scraps and transition materials produced in the production process of different production processes. Moreover, the odor grade does not meet the requirements of GB/T 40006.1-2021 standard, and according to GB 34330-2017 standard, the sample is determined to be solid waste.

(The above content is taken from the speech at the 28th China Plastic Recycling and Recycling Conference in Ningbo on November 7, 2023)

Previous:Global promotion of carbon red...

Next:POM capacity expansion after t...