2024.01.10

Research progress of waste plastics separation technology: density separation, optical separation, electric separation, solvent separation

Page view:479

The separation technology of waste plastics is an important link to realize the efficient recycling of waste plastics, and is also a key step to realize the homogenization of waste plastics, ensure the stable operation of the subsequent process and the stability of the product. In this paper, the research progress of density separation, optical separation, electric separation and solvent separation are introduced. The future research direction is put forward, including the development of integrated and intelligent sorting system, increasing the research of solvent sorting, and developing cascade sorting technology, which has positive significance for the research and development of waste plastic sorting technology and improving the resource utilization of waste plastic.

Source: Journal - Petroleum Refining and Chemical Industry Volume 54 Issue 10 October 2023

Authors: LI Chenghao, ZOU Liang, WANG Shuqing, XU Run

introduction

Recycling of waste plastics mainly includes physical (mechanical) recycling, chemical recycling and so on. Whether it is physical recycling or chemical recycling, it is necessary to pretreat waste plastics to a certain extent, such as impurity removal, cleaning, crushing, sorting, etc., among which, the sorting of waste plastics is relatively complex and difficult, and it is also the core step of waste plastic pretreatment technology.

Waste plastics have the characteristics of complex composition. For physical recycling, it is necessary to divide them into plastics with single components as far as possible before recycling, and then independently recycle them according to the nature of different kinds of plastics. For chemical recycling, especially the more widely used pyrolysis technology recovery method, waste plastics need to be pre-removed halogen-containing plastics to ensure product quality and reduce the safety risks of production equipment, which requires the separation and sorting of waste plastics to be as thorough as possible. The traditional sorting method is mainly manual sorting, which requires high requirements for sorting personnel and rich experience, relatively low sorting efficiency and high labor cost. Although the current manual separation can not be completely replaced, but through the unremitting efforts of scientists, the separation technology of waste plastics has also made some progress, magnetic separation, supercritical fluid separation and other methods have been developed.

In this paper, the research progress of density separation, optical separation, electric separation and solvent separation was systematically reviewed, and the advantages and disadvantages of different separation technologies were compared and expounded. Suggestions for future research and development of separation technologies were put forward, in order to provide support for the research and development and application of waste plastics separation technology.

Density separation

Density separation is a classification method based on the density difference of different types of plastics. The common plastic density is shown in Table 1. The separation effect of this technology is greatly affected by factors such as the particle size and shape of plastics. At present, the density separation technology widely used is mainly float and sink separation and wind separation.

2.1

Float and sink sorting

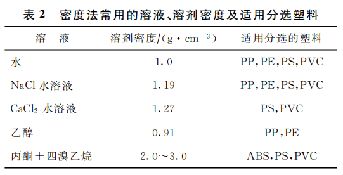

Float and sink separation mainly uses the buoyancy difference of different kinds of plastics in the same solvent to carry out separation method. This method has a good separation effect on different types of plastics with large density differences, but it is relatively difficult to separate plastics with similar density, and it is difficult to achieve the separation of mixed waste plastics. At the same time, the method is greatly affected by the cleanliness of plastics, and waste water will be generated during the separation process. At present, the density of solution and solvent commonly used by density method and the suitable sorting plastics are shown in Table 2.

Table 2 Density of solution and solvent commonly used in density method and suitable for sorting plastics

2.2

Air separation

Wind separation is a method of sorting according to the difference of density, shape and particle size of different plastics, resulting in different distances in the air flow. This method can not only realize the separation of plastics with large density differences, but also better remove the metal or stone sand with large density in plastics. However, due to the difference in particle size of mixed plastics or the density change caused by additives, the accuracy of wind separation is low and the error is large. In order to improve the separation accuracy, wind separation often needs to be combined with other separation technologies to achieve efficient separation of different plastics. At present, the wind separation equipment mainly includes the wind separation machine and the separation shaking table. Among them, the wind separator mainly includes vertical, horizontal and vortex type wind separator.

Optical separation

Optical separation is one of the important ways in the separation of waste plastics, which mainly uses the spectral difference of different kinds of plastics for separation. At present, optical separation mainly includes infrared spectrum separation, X-ray fluorescence separation (XRF separation), Raman spectrum separation, laser induced breakdown spectrum separation (LIBS separation), hyperspectral imaging technology separation (HSI separation), etc., which is one of the main research directions of plastic separation technology.

3.1

Infrared spectral sorting method

Infrared spectrum sorting is one of the most widely studied technologies, including near-infrared spectrum sorting and mid-infrared spectrum sorting. Among them, near-infrared spectrum sorting is regarded as the most potential technology for commercialization due to its advantages of high speed and high precision.

In 1995, Scott et al. used near infrared spectroscopy to identify the characteristic absorption peaks of PET plastics at wavelength 1660nm and polyvinyl chloride (PVC) plastics at wavelength 1716nm, and realized the efficient identification and sorting of the two types of plastics. The technology has also been applied to the sorting and identification of broken dirty bottles.

The physical and chemical properties of ABS,PS and PP are similar, which has always been the difficulty of plastic separation. In 2018, LiJia et al. reported an automated online identification and sorting technology for ABS, PS, and PP plastics. The technology conducted online dynamic analysis of the near-infrared spectrum of plastics in the range of 1050~1350nm through self-designed software, combined with an air blowing system. It achieves efficient separation of ABS,PS,PP mixed plastics that are difficult to separate, and the separation accuracy is higher up to 99%.

Subsequently, ZhuShichao et al. developed a solid waste sorting and identification system based on near infrared spectroscopy detection and analysis, combined with the PCR-SVM (principal component analysis - support vector machine) classification model, and realized the efficient identification of PP, PS, PE, polymethyl methacrylate (PMMA), ABS and PET plastics. The accuracy of the identification was up to 97.5%.

In 2021, DuanQinyuan et al. proposed a test and analysis method combining PCA, SVM, linear discriminant (LDA) and partial least square discriminant analysis (PLS-DA) by using near infrared spectroscopy. The classification of PET, high density polyethylene (HDPE),PVC, low density polyethylene (LDPE),PP,PS and PC was realized. The research results showed that the classification accuracy of PET,PVC,PP,PS and PC plastics could reach.

In addition to the above studies, NIR spectroscopy has also been applied to the classification of waste electrical and electronic equipment (WEEE) plastics. To sum up, the near infrared spectral separation method is a reliable and mature mixed plastic separation technology, France SydelEnsemblierIndustriel company developed DIBOP system is using near infrared spectroscopy for the PVC, PET, HDPE plastic bottle sorting. Subsequently, a more convenient handheld near-infrared spectrometer has also been developed, and is widely used in plastic sorting.

Although NIR spectroscopy has been used in the identification of plastic and wooden products, it is difficult to pass NIR spectroscopy sorting because black plastic has a low reflection coefficient and no obvious NIR spectral signal. In 2017, Rozenstein et al. tested the mid-infrared spectral reflection of 234 different colors of transparent plastic samples and 29 wood and paper samples, especially identifying the mid-infrared characteristic absorption peak of black plastic products, solving the problem that such plastics could not be identified due to limited detection in the near infrared region. The separation of PET, PE, PVC, PP, PLA (polylactic acid), PS and other waste plastics was realized. In addition, Kassouf et al. also used mid-infrared spectroscopy, combined with independent component analysis (ICA), to achieve the efficient separation of PET,PE,PP,PS,PLA plastics.

3.2

X-ray fluorescence separation (XRF Separation)

X-ray fluorescence separation method is a method that uses X-ray irradiation to excite target atoms, and then the excited ions return to the ground state to produce fluorescence spectra to achieve separation. In 1994, Kenny et al. used XRF separation method to achieve the separation of PET and PVC plastics. In 2010, Bezati et al. took PP plastics as an example and proposed a tracer-based XRF plastic separation method by adding different rare earth oxides as tracers. Chinese researchers have also conducted research on XRF sorting plastics, and in 2019, Ginger Dividend has realized the efficient sorting of different pharmaceutical aluminum-plastic packaging sheets and black plastic bags with XRF sorting method. XRF separation method has the characteristics of high sensitivity, convenience and speed, so it has also been concerned and studied by companies.

NationalRecoveryTechnologies company implements the XRF sorting the commercialization of plastics, the company using the X-ray detection after confirmation of PVC products, PVC plastic will be detected through the air from being blown out, the success of PVC plastic was isolated from a plastic mixture. This machine is called Vinylcycle, and it's the world's most powerful photoelectric sorter.

In summary, XRF separation technology is an efficient method for separating PVC, but it is still difficult to detect PVC plastic covered by other plastic products. Integration and miniaturization are the development direction of current instruments, and handheld X-ray fluorescence spectral sorting equipment has also been developed. In 2023, Chaine et al. studied the industrial sorting of WEEE plastic [taking the whole flat panel display equipment (FPD) plastic shell as an example]. In summary, XRF separation is a fast, lossless and effective separation technology.

3.3

Raman spectral separation method

Raman spectrum separation method is to obtain the position and intensity information of the characteristic peaks of the plastic samples by analyzing the other frequencies of the light irradiated on the plastic samples that are different from the incident light frequencies, and then compare with the Raman spectra of the standard materials to determine the types of plastics and realize the sorting work of plastics.

In recent years, scientists have also carried out research in the separation of waste plastics by Raman spectroscopy. In 1999, Allen et al. used Raman spectroscopy to realize the efficient identification of PE,PET,PP,PS,PVC and other plastics. In 2009, Tsuchida et al. applied the high-speed Raman spectroscopy and multi-element analysis method to the online sensing system, successfully realized the efficient identification and classification of broken plastics in the recycling plant, and the plastic quality was classified by the numerical discriminant analysis. Subsequently, Dong Juan et al. realized the separation and identification of food packaging plastics by Raman spectral separation method, with a degree of up to 95%.

In general, the Raman spectral separation method has the advantages of non-destructive to the sample, sensitive detection, high accuracy, low humidity requirements for plastics, and wide applicability of plastics, especially for the identification of plastic fragments with a plastic size of less than 20μm. In recent years, this technology has played an important role in the identification and separation of microplastics, and is one of the important means of plastic separation. However, the method also has a serious problem of interference by plastic impurity signals, which greatly affects the detection rate and accuracy of the method, and the technology is slow to identify plastics, so it is difficult to meet the fast identification standards required by industry.

3.4

Laser induced breakdown spectroscopy (LIBS) sorting method

Laser-induced breakdown spectral sorting method is used to detect and analyze the spectral frequency and intensity emitted by plasmas on the surface of plastics irradiated by intense laser, so as to identify the types of plastics, which has been widely concerned and studied by scientists in recent years.

In 1998, Sattmann et al. used laser-induced breakdown spectroscopy and feedforward neural network algorithm to realize the classification and recognition of HDPE,LDPE,PET,PP and PVC, and achieved good classification and recognition results. In 2006, Anzano et al. used laser induced breakdown spectroscopy to achieve rapid identification and sorting of e-waste plastics ABS,PS,PE,PC,PP,PA. Subsequently, Gondal et al. also studied the separation of HDPE,LDPE,PS,PP,PET and PVC plastics by LIBS in detail, and the study showed that LIBS is an effective tool for quickly classifying different types of plastics and plays an important role in waste management.

In 2011, Boueri et al. used laser induced breakdown spectroscopy of 240~820nm band, combined with artificial neural network algorithm, to achieve efficient identification of PP, PVC, polytetrafluoroethylene (PTFE), POM, PE, PA, PC, PMMA plastics, the recognition rate can reach 81%~. Subsequently, Pereira-Filho et al. established a model for efficient analysis and classification of waste plastics ABS and PC, which can be quickly analyzed and sorted with no or very little pretreatment. Recently, Junjuri et al. used fs-LIBS technology (femtosecond laser-induced breakdown spectroscopy) to achieve an efficient separation of HDPE,LDPE,PP,PS, and PET with a degree of 99.53%~.

In summary, LIBS separation method has the advantages of fast analysis, high separation recognition, remote real-time analysis of materials, and simultaneous analysis of a variety of elements. Compared with near-infrared spectroscopy identification method, this technology is less affected by sample surface impurities, does not require sample pretreatment, and has good environmental adaptability. At the same time, the technology is easy to integrate and has good applicability to the identification of relatively difficult black plastic products.

3.5

Hyperspectral imaging (HIS) sorting method

Hyperspectral imaging technology is a new type of separation technology developed in recent years, which combines spectral technology and image technology, and realizes the effective separation of waste plastics by analyzing the collected three-dimensional information of the detected objects.

In 2011, Serranti et al. studied and established hyperspectral imaging analysis and detection technology based on the wavelength range of 400~1000nm vision-near-infrared and 1000~1700nm near-infrared, which can identify polyolefin and pollutants, and can be used to control the quality of polyolefin recycling plants and polypropylene and polyethylene products. In addition, considering the limitations of different optical separation technologies, some combined separation methods have also been reported. In 2017, Shameem et al. realized the separation of PET,PE,PP and PS plastics by combining LIBS and Raman methods. In 2019, Ma Xiao et al. used the technology combined with XRF and infrared spectroscopy to achieve the sorting of 33 kinds of plastic packaging belts.

In summary, optical separation has the characteristics of rich signal information, easy to obtain, high identification of characteristic signals, convenient and fast, sensitive and reliable, non-destructive to samples, etc., and is widely used and promoted. However, most optical separation also has defects such as difficulties in identifying dark plastics, so it needs to be used together with color separation devices.

Electric separation

The electrical separation of waste plastics is a widely used separation technology, which is to charge waste plastics by applying high voltage or friction, and complete the separation of waste plastics due to the different electrical properties and the amount of electricity carried by different plastics. Studies have shown that common plastics from negative to positive charging sequence is: PTFE, PVC, PET, PP, PE, PS, PC, PMMA, polyvinyl alcohol (PVOH). The larger the difference in order, the easier it is for the two plastics to be effectively separated.

In 1978, Pearse et al. used friction electrostatic separation method to achieve PA-66 separation from artificially mixed plastics, with product purity as high as 96%, but the product recovery rate was only 60% to 70%.

Subsequently, Inculet et al. used triboelectrics to achieve the separation of four commercial plastics (PMMA,PE,PVC,PA). The research results showed that this method had a good separation effect on the above plastics, and the purity of the plastic after separation was greater than 95%, and the plastic recovery rate was greater than 98%.

PVC is the most electrically powerful plastic with negative charge in bulk plastics, according to this characteristic, electrical separation technology is also widely used in the separation process of PVC waste plastics. In 2009, Jeon et al. used the friction electrostatic separation method to separate PVC and rubber in communication cable waste, and the PVC recovery rate reached 95.0%.

In 2022, Lyskawinski et al. used electric separation methods to achieve efficient separation of PET and HDPE, and studies have shown that extending the tribological charging time to 5min can effectively improve the sorting efficiency of plastics. ChilworthTechnology also uses this technology to achieve the separation of waste PVC and PET in an applied electric field, with a higher separation degree.

In general, the electric separation has the advantages of small pollution (no waste water generation), good separation effect (can separate the similar density of waste plastics), but for the complex composition of mixed waste plastics there are also problems that need multiple sorting, at the same time, the electric separation is affected by the humidity of waste plastics, plastic characteristics, the size of plastic particles, cleanliness and other factors.

- 5 -

Solvent separation

Solvent separation method is a kind of waste plastics separation method which has been widely studied in recent years. This technology mainly uses the difference of solubility of different kinds of plastics in the same solvent to realize the separation and recycling of different kinds of waste plastics. At present, the choice of solvents mainly follows the principle of similar phase dissolution and the principle of similar solubility parameters.

In 2009, Achilias et al. used solvent dissolution and reprecipitation technology to realize the recycling of LDPE,HDPE,PP,PS,PVC,PET materials of food, medicine and detergent packaging. At the same time, the research group also tested the properties of recycled materials, and the research showed that: The properties of the recovered materials are basically the same as those of the original materials, and only a few of the recovered materials are slightly degraded.

In 2020, Walker et al. achieved the separation of PE,EVOH and PET composite films by solvent method, and successfully obtained a single component of plastic. Subsequently, Nieminen et al. used the solvent method to separate aluminum foil and plastic from discarded pharmaceutical packaging. In recent years, Sinopec Petrochemical Research Institute Co., Ltd. has also carried out systematic research on the selective dissolution of plastics.

The separation of waste plastics by solvent separation has the advantages of good product adaptability, high quality of plastics after separation, simple operation, etc., but with the increasing price of chemical products, solvent costs are also increasing, economic problems are prominent, and the overall energy consumption is also the main difficulty that needs to be solved by this technology.

- 6 -

Conclusions and recommendations

Waste plastic pretreatment technology is the step to realize the recycling of waste plastics, and waste plastic sorting technology is the core step of pretreatment technology, but also the key link to ensure the high-value reuse of waste plastics. With the continuous progress of science and technology and the continuous increase of China's environmental protection, waste plastic sorting technology has also been developed by leaps and bounds. However, the existing technology is generally difficult to take into account the sorting accuracy and economy, the efficiency of single sorting technology needs to be improved, and the integration degree of combined sorting process is not high, which greatly limits the recycling process of waste plastics.

In response to the above problems, research can be carried out in the future from the following aspects to further improve plastic sorting technology:

Develop an integrated, miniaturized and intelligent sorting system to improve the efficiency, accuracy and convenience of sorting technology.

Increase the research on solvent separation technology. Solvent separation has the characteristics of simple operation, thorough plastic separation, high quality of recycled plastics, and recycled materials can be further used as raw materials for granulation or direct degradation, is a very potential separation technology, should be paid great attention to. In view of the existing shortcomings of this technology, the solvent separation and recovery process can be optimized to further reduce the amount of solvent, establish an energy recycling system, reduce energy consumption and improve economy.

Development of step sorting technology. According to the advantages and disadvantages of existing technologies, combined with the characteristics of mixed waste plastics themselves, different sorting technologies are integrated to improve sorting efficiency, reduce energy consumption, and maximize the advantages of sorting technology.

To sum up, the development of waste plastic sorting technology with high efficiency, high precision, good economy, energy saving and environmental protection is still the direction of future research and deep cultivation. The new and efficient waste plastic sorting technology will also greatly promote the development of the circular economy and help the early realization of the "double carbon" goal.

Previous:An environmental emergency has...

Next:The recovery rate of low-value...